Electric linear actuators have become a fundamental component in modern automation, offering precise and reliable motion control across various industries. Unlike traditional hydraulic or pneumatic systems, which rely on fluid pressure or compressed air, electric actuators convert rotary motion from a motor into smooth, controlled linear movement. This makes them ideal for applications requiring high precision, efficiency, and automation.

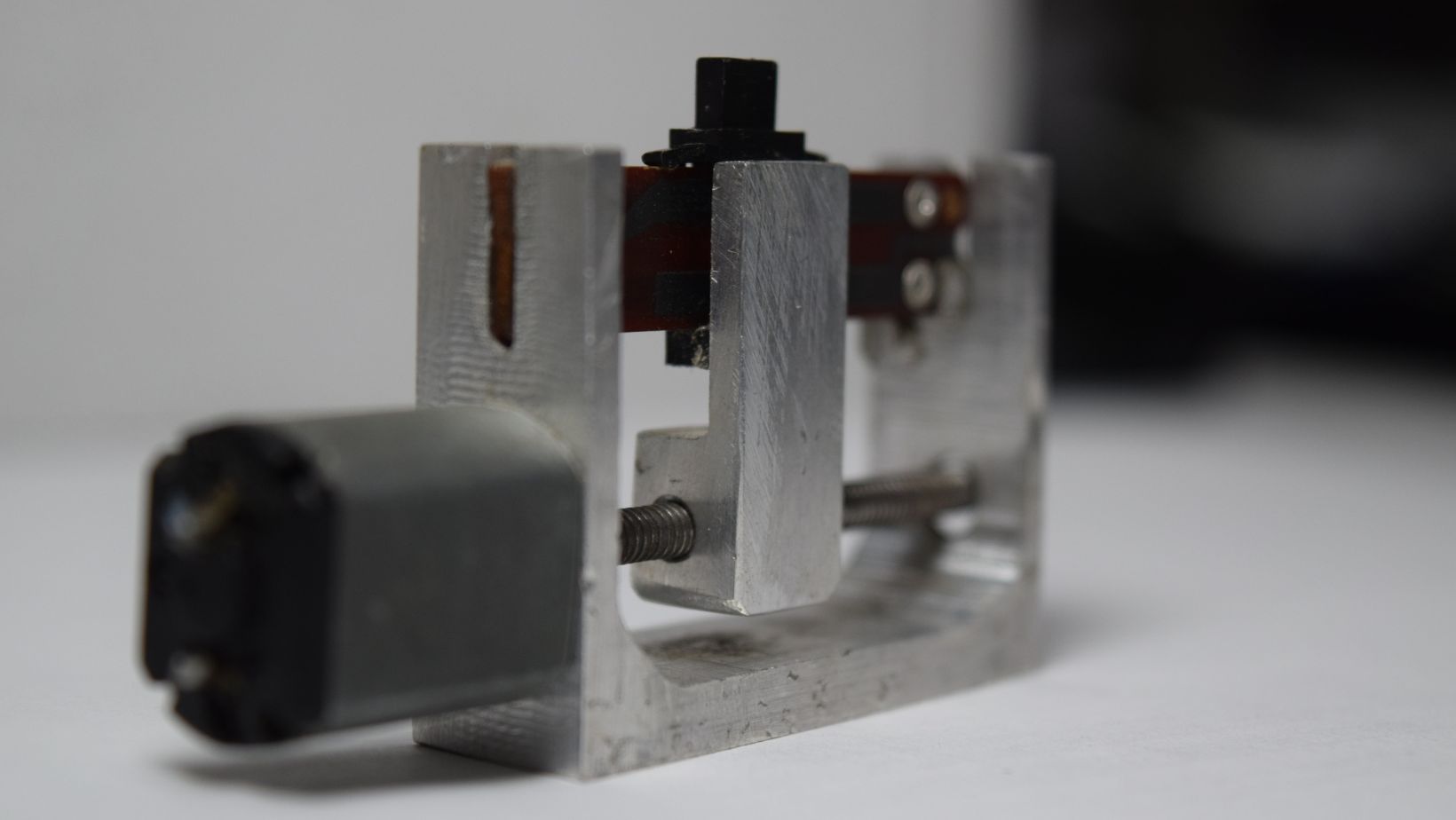

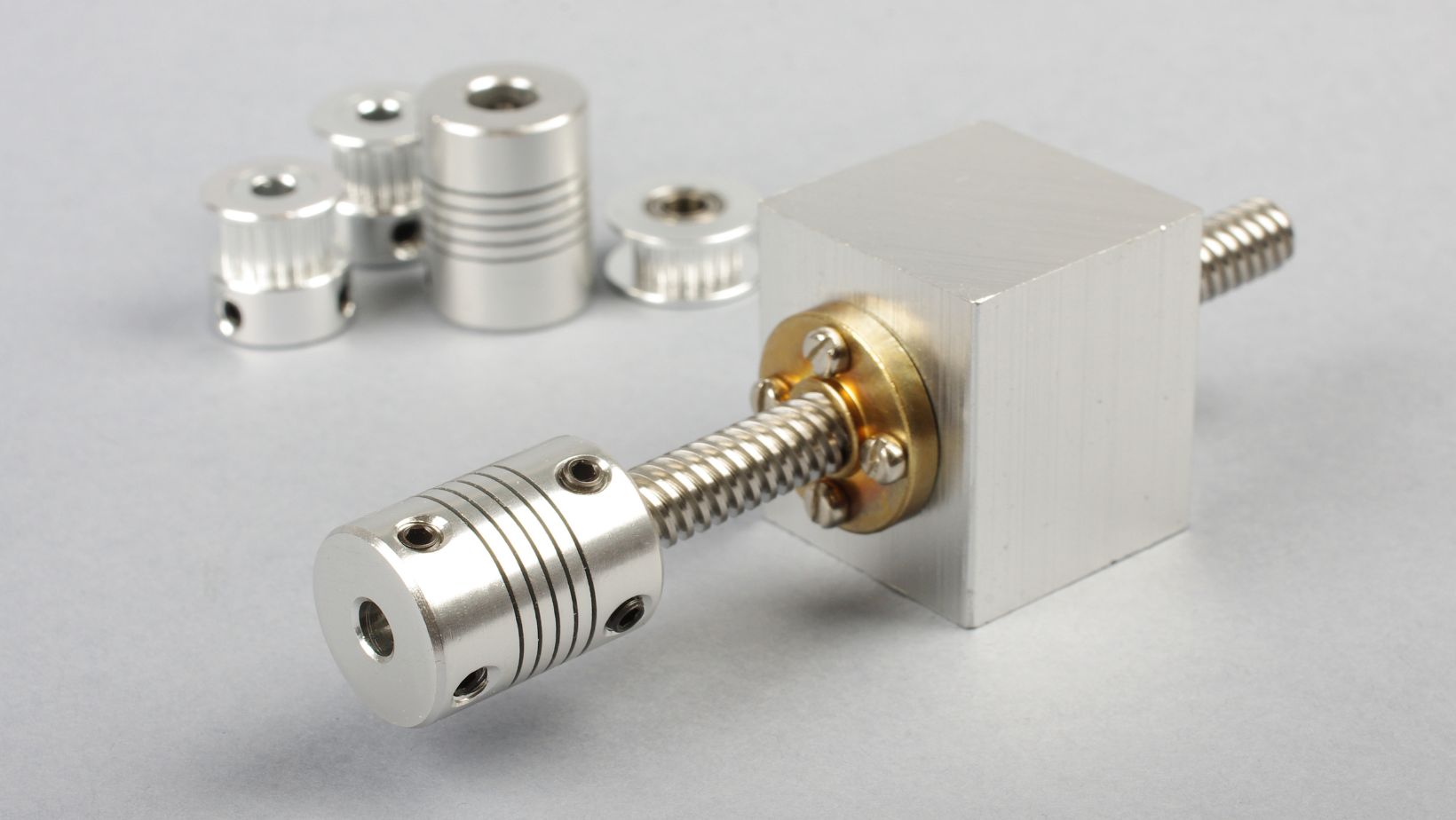

Electric linear actuators operate using a motor-driven lead screw or ball screw mechanism, allowing for controlled movement along a straight path. They can be programmed for specific motion sequences, integrated with sensors, and remotely controlled, making them a key technology in smart systems.

One of the biggest advantages of electric linear actuators is their energy efficiency, since they don’t require pumps, valves, or air compressors, they consume less power and generate minimal waste. Additionally, they offer superior precision, allowing for fine-tuned positioning without performance fluctuations. Their low maintenance requirements further enhance their appeal, as there are no leaks, pressure losses, or fluid contamination issues common in hydraulic and pneumatic alternatives. As industries move toward smarter and more sustainable solutions, electric linear actuators are leading the way in transforming motion control technology.

Ultimate 3 Advantages of Electric Linear Actuators

People value not only ideas and solutions but first of all the benefits they can receive while using this or that device. Modern actuators possess lots of advantages and can be applied for diverse purposes, no matter what it is home automation or industry area. Let’s see what we can get with these small units.

Precision and Accuracy

One of the biggest advantages of electric linear actuators is their precision. Unlike hydraulic or pneumatic systems that rely on fluid or air pressure, electric actuators move with complete control. This makes them perfect for applications that require fine-tuned, repeatable movement.

For example, in the medical field, surgical robots use electric actuators to position tools with extreme accuracy. Even a fraction of a millimeter matters in delicate procedures, and electric actuators ensure smooth, precise motion without sudden shifts or pressure drops.

Energy Efficiency

Electric actuators consume less energy compared to hydraulic and pneumatic systems. Since they don’t rely on external pumps or air compressors, they use only the electricity needed to move and hold a position. This makes them an excellent choice for applications where energy conservation is important.

A great example is solar panel tracking systems. These actuators adjust panel angles throughout the day, ensuring they capture the most sunlight. By using minimal power, they help improve solar energy efficiency while keeping operational costs low.

Minimal Maintenance

Another major benefit of electric linear actuators is their low maintenance. Hydraulic systems require regular fluid checks and can suffer from leaks, while pneumatic systems need constant air pressure adjustments. Electric actuators, on the other hand, don’t require fluids, seals, or extensive upkeep.

This makes them ideal for smart home automation. Adjustable desks, automated blinds, and even recliner chairs often use electric actuators to provide smooth and quiet motion. Since they last for years with minimal servicing, they’re a reliable choice for both homes and industries.

In short, electric actuators offer precise movement, save energy, and require little maintenance, making them a smart choice for modern automation.

Applications Across Industries

Electric linear actuators have found their way into a wide range of industries, transforming the way machines and systems operate.

Manufacturing & Automation

In industrial automation, electric linear actuators are widely used to improve production efficiency and reduce reliance on manual labor. In robotic assembly lines, these actuators help position parts with precision, ensuring that every movement is repeatable and consistent. Automated welding systems also rely on actuators to control the motion of welding arms, guaranteeing accuracy and reducing material waste.

One of the most common applications in manufacturing is in conveyor belt systems. Electric actuators adjust belt positions, control loading and unloading processes, and help maintain a seamless flow of materials. By automating these tasks, manufacturers can significantly improve productivity while reducing operational costs.

Healthcare & Medical Equipment

The medical industry depends on electric actuators for a wide range of applications that improve patient comfort and safety. Adjustable hospital beds use actuators to modify height and tilt, making it easier for caregivers to assist patients. Similarly, MRI machines use actuators to move scanning components smoothly and quietly, ensuring precision without disturbing patients.

Another critical use is in robotic prosthetics and assistive devices. These actuators enable controlled, natural movement, improving mobility for individuals with disabilities. Patient lifts also benefit from electric actuators, allowing for safe and efficient transfers with minimal strain on healthcare providers.

Aerospace & Defense

In aerospace applications, precision and reliability are non-negotiable. Electric actuators are used in aircraft wing flaps and landing gear systems, ensuring controlled movements during takeoff and landing. Unlike hydraulic systems, which require extensive maintenance and can be affected by temperature fluctuations, electric actuators offer a cleaner, more energy-efficient alternative.

Space exploration also benefits from actuator technology. Satellites and space telescopes rely on actuators to adjust lenses and antennae for optimal positioning. Since repairs are impossible in deep space, these systems must operate flawlessly for years. Actuators provide the necessary precision to keep these instruments aligned, ensuring they capture high-quality data from the farthest reaches of the universe.

Automotive & Transportation

The automotive industry is increasingly integrating electric actuators into vehicle systems to enhance performance and user experience. Modern electric vehicles (EVs) use actuators in charging stations, ensuring that charging connectors align perfectly with ports. Actuators also play a role in adjustable seating and steering systems, allowing for greater comfort and customization for drivers and passengers.

One of the most advanced uses is in adaptive suspension systems. These actuators adjust a vehicle’s suspension in real-time, responding to road conditions to improve stability and ride comfort.

Renewable Energy & Sustainability

As the world shifts towards cleaner energy sources, electric actuators are playing an important role in maximizing efficiency. Wind turbines use actuators to adjust blade angles based on wind speed, ensuring optimal energy generation. Similarly, solar panel tracking systems rely on actuators to follow the sun’s movement, increasing the amount of captured solar energy.

Another critical application is in hydroelectric power plants, where actuators control dam gates to regulate water flow. These systems must operate with extreme precision to maintain energy output while preventing damage from sudden pressure changes.